Description

Fleck Meter Valve 2510/1650

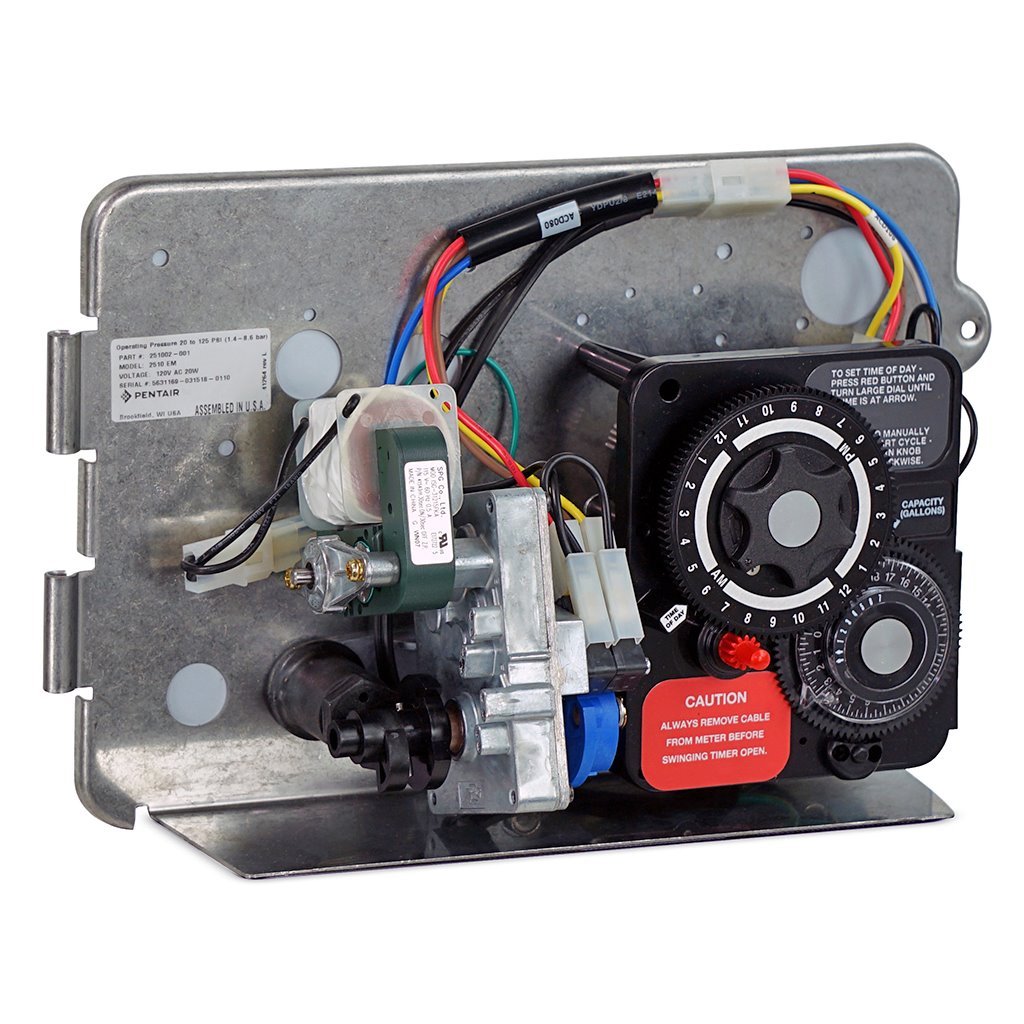

The Fleck Meter Valve 2510/1650 is a high-capacity, robust, and reliable valve designed for advanced control in water treatment systems. It is engineered for efficiency and longevity, ensuring optimal performance in various water treatment applications.

Features:

-

High Flow Rates:

- Designed to handle high flow rates, making it suitable for commercial and industrial applications.

-

Durable Construction:

- Made with high-quality materials to withstand the demands of heavy-duty use.

-

Advanced Control:

- Offers advanced control features for precise and efficient operation of water treatment systems.

-

User-Friendly Interface:

- Provides a user-friendly interface for easy programming and monitoring.

-

Versatile Compatibility:

- Compatible with various types of water treatment systems, including softeners and filters.

Commercial Applications:

-

Restaurants and Food Service:

- Ensures a consistent supply of treated water for food preparation, cleaning, and other needs.

-

Hospitality Industry:

- Provides hotels and resorts with reliable water treatment for guest use, amenities, and other applications.

-

Office Buildings:

- Offers businesses a solution for ensuring access to high-quality water for employees and operations.

Industrial Applications:

-

Manufacturing:

- Ensures the availability of treated water for various manufacturing processes, contributing to product quality and operational efficiency.

-

Food and Beverage Production:

- Provides consistent water quality for food and beverage production, ensuring product safety and quality.

-

Chemical Processing:

- Offers reliable water treatment for chemical processing industries, ensuring water quality standards are met.

Advantages in Commercial and Industrial Settings:

-

Efficient Water Treatment:

- Ensures efficient and reliable water treatment, providing consistent water quality for various applications.

-

Cost-Efficiency:

- Enhances the efficiency of water treatment systems, leading to cost savings on water usage and maintenance.

-

Reliable Performance:

- Offers reliable performance, ensuring uninterrupted operation and minimal downtime.

-

Ease of Use:

- The user-friendly interface allows for easy operation and monitoring, ensuring optimal performance at all times.

-

Versatility:

- Its compatibility with various systems makes it a versatile choice for different water treatment applications.

Fleck Meter Valve 2510/1650 stands out as a comprehensive solution for water treatment control in both commercial and industrial settings. Its advanced features, reliable performance, and compatibility with various systems make it a valuable investment for ensuring consistent access to high-quality water for diverse operational needs. Opting for the Fleck Meter Valve 2510/1650 is a step towards enhanced operational efficiency, cost savings, and a commitment to delivering quality and safety in all water-related aspects of commercial and industrial operations.

Fleck Meter Valve 2510/1650

Yoke, by-pass, cover, and backwash flow control assembly sold separately.

Meter-initiated regeneration for maximum salt efficiency. Standard meter range: 125 – 2,125 gals. Extended meter range: 625 – 10,625 gals. available. 24 K label provided.

ITEM SPECIFICATIONS

-

Meter

-

2510

-

7.65 lbs per EA

Fleck Meter Valve 2510/1650 Installation and Programming

The installation and programming of the Fleck Meter Valve 2510/1650 are crucial steps to ensure its optimal performance and efficiency in water treatment systems. Below is a guide to help understand the installation and programming process:

Installation:

Preparation:

-

Gather Necessary Tools and Equipment:

- Ensure you have all the necessary tools and equipment for installation.

-

Choose an Appropriate Location:

- Select a suitable location for the water treatment system and valve, ensuring it is easily accessible for maintenance and monitoring.

Installation Process:

-

Turn Off the Water Supply:

- Ensure the water supply is turned off before starting the installation process.

-

Position the Valve:

- Place the Fleck Meter Valve 2510/1650 on the top of the tank, ensuring it is securely fitted.

-

Connect Plumbing:

- Connect the plumbing to the valve, ensuring all connections are secure to prevent leaks.

-

Attach Bypass or Yoke:

- Attach the bypass or yoke to the valve as per the manufacturer's instructions.

-

Connect Drain Line:

- Securely connect the drain line to the valve.

-

Turn On the Water Supply:

- Gradually turn the water supply back on and check for any leaks. Make adjustments as necessary.

Programming:

-

Access the Control Panel:

- Access the control panel on the valve to begin the programming process.

-

Set Time and Day:

- Set the current time and day on the control panel.

-

Enter Water Hardness:

- Enter the water hardness level, which can be obtained from a water test.

-

Set Regeneration Time:

- Program the regeneration time based on your water usage and system capacity.

-

Enter Additional Settings:

- Enter any additional settings as per your specific water treatment system and requirements.

-

Save Settings:

- Ensure to save all the settings entered to ensure the valve operates as programmed.

Tips for Successful Installation and Programming:

-

Refer to the Manufacturer’s Manual:

- Always refer to the manufacturer’s manual for detailed instructions and specifications.

-

Ensure Proper Sealing:

- Ensure all connections are properly sealed to prevent leaks and ensure efficient operation.

-

Test the System:

- After installation and programming, test the system to ensure it is operating correctly.

-

Seek Professional Assistance:

- If unsure about the installation or programming process, it is advisable to seek assistance from a professional plumber or water treatment technician.

Proper installation and programming of the Fleck Meter Valve 2510/1650 are essential for ensuring the optimal performance and longevity of your water treatment system. Following the above steps and tips, along with referring to the manufacturer’s instructions, will help in achieving a successful installation and programming process, ensuring reliable and efficient operation of the valve and the associated water treatment system.

Overview

- ? U.S.-based support and expert assistance

- ?? Built with trusted Pentair & Fleck components

- ?? Ships nationwide - freight-safe packaging

- ?? Ideal for residential and light-commercial systems

Specs (Typical)

| Max Operating Pressure | 125 psi |

|---|---|

| Max Water Temp | 100 ?F |

| Electrical | 120 V AC |

| Flow Range | 5-45 GPM (model dependent) |

Related: Control Valves . Parts . Get sizing help