Phosphates in Private Well Water: Causes, Risks, Testing & Treatment (Plus Proven Equipment Options)

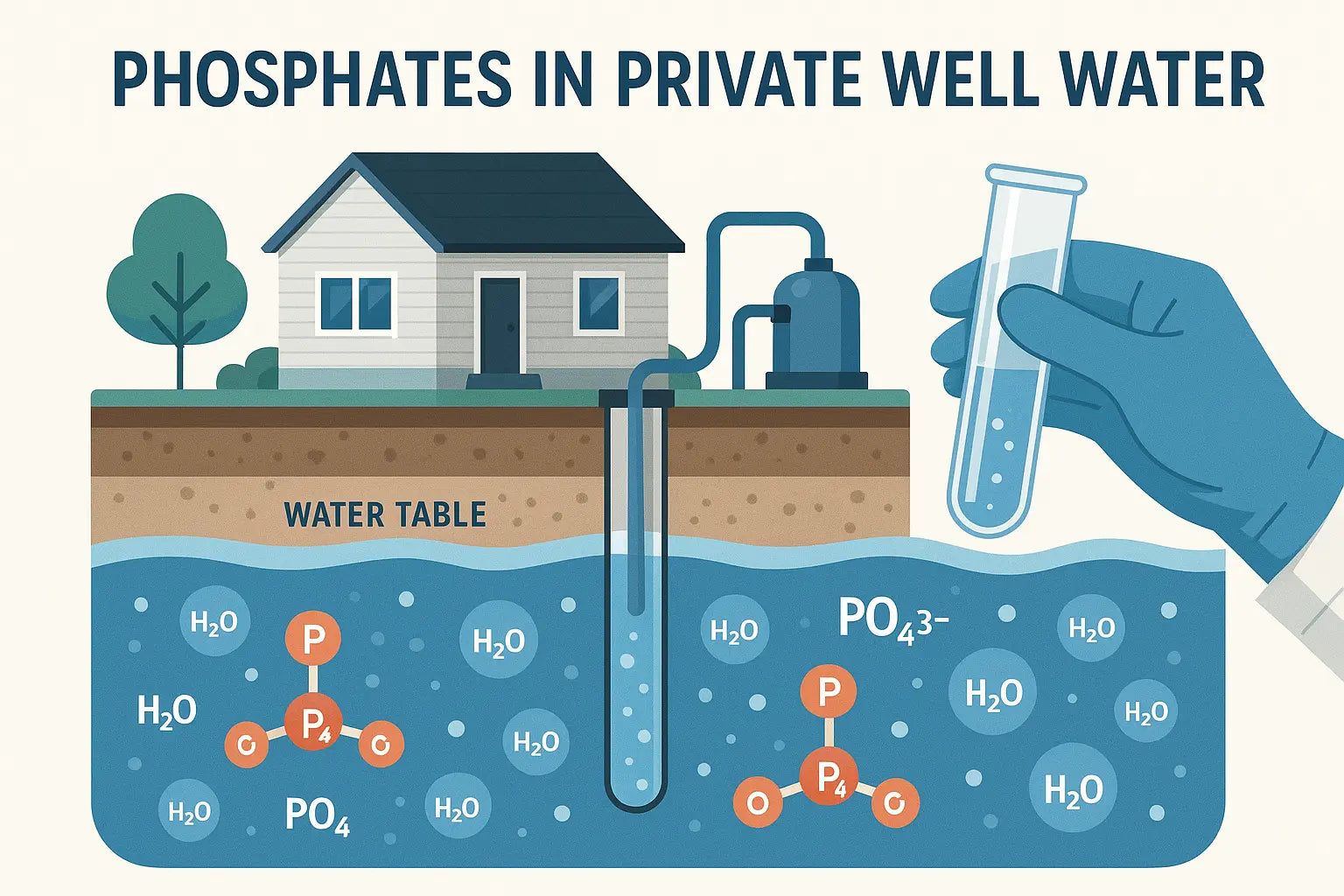

1) Phosphate 101—what it is and why it shows up in wells

What are “phosphates”? In water, “phosphate” often refers to phosphorus present as orthophosphate (reactive; readily measurable), condensed/polyphosphate (chains that can revert to orthophosphate), and organic phosphorus bound in biomolecules. Phosphorus is a nutrient—too much in surface waters can drive eutrophication (algae blooms and low oxygen).

Why in a private well? Many soils bind phosphorus well, limiting its migration; however, sandy/karst soils, shallow wells, heavy fertilizer or manure use, or septic leakage can allow phosphate to enter the aquifer feeding a well.

Municipal vs. private wells: Public water systems often add orthophosphate as a corrosion inhibitor (to control lead/copper release from plumbing). Private wells typically do not need this addition unless a homeowner or service provider doses sequestrants on site.

2) Health & regulatory context—what’s the actual risk?

- No federal MCL for phosphate: Phosphate is not on the EPA’s list of enforceable primary drinking‑water standards. Private wells are unregulated; owners are responsible for testing and treatment.

- Indirect concerns: At typical groundwater concentrations, phosphate is rarely a direct health driver. The bigger issues are nuisance growth (biofilms/algae in storage), equipment fouling/complexation, and the possibility it signals surface influence—often accompanied by nitrate or microbes that do carry health risk.

3) How phosphate gets into your well (and what you can do upstream)

Common sources near homes and farms

- Fertilizer and manure application on lawns, gardens, and fields (including legacy soil phosphorus).

- Septic systems (household wastewater contains phosphorus; poorly sited or failing drainfields can leach nutrients).

- Animal operations and uncovered manure storage.

- Surface water infiltration near the wellhead (damaged cap, shallow casing, flood‑prone siting).

- Intentional dosing of poly/orthophosphate for metal sequestration in onsite treatment systems.

Simple prevention checklist

- Maintain a 50–100 ft no‑fertilizer buffer upslope of the well; redirect roof/driveway runoff away from the wellhead.

- Inspect the well cap, casing, annular seal, grade annually; raise or fix if prone to inundation.

- Service septic tanks on schedule; correct saturated or sluggish drainfields.

- If you dose sequestrants to control iron/manganese, reassess the need and dose or switch to physical oxidation/filtration.

4) Testing your well for phosphate (and what the numbers mean)

What to test—and how often

Because phosphate can flag surface influence, pair it with nitrate/nitrite, total coliform/E. coli, and basic chemistry. Many state programs suggest annual bacteria and nitrate checks; add phosphate if you suspect fertilizer influence or see slime/algae in storage.

Sampling tips

- Use a clean, non‑reactive bottle (lab‑provided when possible).

- Flush the tap several minutes; avoid aerators when sampling.

- Follow the lab’s preservation instructions (orthophosphate vs. total P may differ).

- Pay attention to units: mg/L as P vs. mg/L as PO4.

Conversion: mg/L as PO4 ≈3.066 × mg/L as P.

Test methods & options

- Field kits: Colorimetric (ascorbic acid / molybdenum‑blue) kits are good for spot checks and trending.

- Lab methods: Standard Methods 4500‑P E (Ascorbic Acid) or EPA 365.3 measure orthophosphate and total phosphorus (after digestion) to low ranges.

How to read the result

No federal health‑based limit exists for phosphate. For drinking water, concern increases if phosphate coincides with nitrate or bacteria (surface influence) or with plumbing issues (slime, taste/odor, scaling complexes). For maintenance, many homeowners act when orthophosphate > ~0.1–0.3 mg/L as P fuels slime growth in storage or filters (a practical threshold, not a regulation).

5) Treatment that works in homes (and what to buy)

The right approach depends on your goal:

- Pristine drinking/cooking water at one faucet: Install Point‑of‑Use (POU) Reverse Osmosis (RO). RO membranes typically achieve high phosphate rejection alongside many other contaminants.

- Whole‑home equipment protection & fewer odors/slime: Use sediment and catalytic carbon pretreatment; keep RO at the kitchen sink for polishing.

- Full‑home polishing / high‑volume needs: Consider whole‑home RO (more common for farms/small businesses) or specialty adsorptive media that bind oxyanions like phosphate.

A) Point‑of‑Use RO (under‑sink) for drinking & cooking

Why RO? A semipermeable membrane rejects dissolved ions and many organics. Real‑world performance depends on pressure, membrane type, temperature, and maintenance, but phosphate removal is typically high.

Good fits from Water Softener Plus (links open in new tabs):

-

Under‑Sink Alkaline RO Water Filter (50 GPD)

Adds remineralization for taste after RO. -

Reverse Osmosis System — 5 Stage (50 GPD)

Compact, serviceable, widely compatible filters.

Sizing & maintenance tips

- Capacity (GPD): 50–75 GPD suits most families.

- Space & tank: Ensure under‑sink clearance; tankless saves space but may make noise and demand higher inlet pressure.

- Waste ratio: Typical 3:1–2:1 (brine:permeate); permeate pumps can improve efficiency.

- Filter changes: Sediment/carbon prefilters 6–12 months; RO membrane 24–36 months; post‑carbon ~12 months.

B) Whole‑home pretreatment (keeps equipment happy)

-

In‑Line “Big Blue” Whole‑House Sediment Filter (20″)

First line of defense; reduces particulate food for biofilms and protects downstream gear. -

Upflow Non‑Electric Catalytic Carbon Filter

Improves taste/odor and reduces organics that can co‑travel with nutrients; excellent RO pretreatment.

Note: Catalytic/GAC carbon doesn’t directly remove phosphate (an anion). It improves overall water quality and reduces organics that feed biofilms, making phosphate management easier downstream.

C) Specialty adsorption (iron/aluminum‑based media) & hybrid systems

Iron‑hydroxide and other engineered adsorbents readily bind oxyanions like phosphate. Consider these when RO isn’t practical or as polishers:

-

ArsenicSafePlus

Adsorptive media system; product literature notes reduction of phosphate along with arsenic, silica, and certain metals. -

FluorideRemovalPlus

Adsorptive media system listing phosphate among targeted species; check capacity and pH suitability.

D) Whole‑home / high‑volume RO (farms, small businesses)

For sites that need consistent low‑nutrient water at volume (e.g., dairies, food production), whole‑home or light‑industrial RO can make sense with proper pretreatment and storage.

Industrial Reverse Osmosis System (6400 GPD)

- Pretreat for sediment, iron/manganese, and hardness to protect membranes.

- Plan for brine disposal, storage tank, repressurization pump, and bypass plumbing.

- Expect higher maintenance and professional commissioning.

6) Putting it together—three practical setups

Goal A: Ultra‑low phosphate for drinking/cooking (typical household)

Big Blue sediment → optional catalytic carbon → under‑sink RO → faucet/ice line.

Goal B: Reduce slime/odor and protect equipment whole‑home

Well → Big Blue sediment → Upflow Catalytic Carbon → (softener, if used) → house; keep RO at the sink.

Goal C: Farm/small enterprise needing low‑nutrient water everywhere

Sediment + iron/manganese + softening → whole‑home/industrial RO → storage + UV (if needed).

7) Maintenance matters—how to keep systems working (and safe)

Testing cadence (suggested)

- Every 6–12 months: Orthophosphate (field kit), nitrate, and total coliform/E. coli through a certified lab; recheck sooner after flooding or heavy fertilizer use.

- After changes: Re‑test after installing new treatment equipment or changing media.

System care

- Replace sediment/carbon on schedule; don’t let spent carbon become a biofilm habitat.

- Watch pressure/flow across filters; sudden drops suggest fouling.

- For RO: track TDS and production rate; spikes or slow output indicate membrane wear or scaling.

- For adsorptive media: follow vendor capacity guidance; validate performance periodically.

8) FAQs

Is phosphate in my well dangerous by itself?

Usually not at typical concentrations, and there’s no federal health‑based MCL for phosphate. The bigger issue is what phosphate indicates (surface influence) and what it does (feeds biofilms) in storage and plumbing.

Why do cities add phosphate while I’m removing it at my sink?

Municipal systems add orthophosphate as a corrosion inhibitor to limit lead/copper leaching. Private wells don’t generally need this, and removing phosphate at the tap helps control biofilm and improves aesthetics.

Will carbon filters remove phosphate?

Not reliably. Phosphate is an anion; RO or adsorptive/anion media are the reliable options. Use carbon for taste/odor and to reduce organics that feed biofilms.

How well does RO remove phosphate?

RO systems commonly achieve high phosphate rejection (often >90%) under typical residential conditions, assuming proper pretreatment and maintenance.

If my phosphate is low, should I still test?

Yes—especially nitrate and bacteria annually. Nutrients can fluctuate seasonally; a clean result today doesn’t guarantee tomorrow’s.

9) Step‑by‑step action plan for well owners

- Baseline lab test: Total coliform/E. coli, nitrate/nitrite; add orthophosphate if you observe slime or have fertilizer/septic risks.

- Quick checks at home: Use a colorimetric orthophosphate kit to trend test monthly in growing season.

- Source control: Adjust fertilizer timing and buffers; inspect the wellhead; maintain the septic system.

- Treat your drinking water: Install a POU RO system (50–75 GPD) and replace filters/membranes on schedule.

- Polish/pretreat whole‑home: Add sediment + catalytic carbon to reduce organics and protect downstream gear.

- Consider specialty media: For added polishing without RO, evaluate an adsorptive cartridge (e.g., ArsenicSafePlus or FluorideRemovalPlus).

- Re‑test: After installation and every 6–12 months thereafter; earlier after floods, land application, or taste/odor changes.

10) Shop the solutions (links verified)

All links below were verified to load as of October 20, 2025.

- Under‑Sink Alkaline RO Water Filter (50 GPD)

- Reverse Osmosis System — 5 Stage (50 GPD)

- In‑Line Water Pre Filter — Big Blue Whole‑House (20″)

- Upflow Non‑Electric Catalytic Carbon Filter

- ArsenicSafePlus (adsorptive media system)

- FluorideRemovalPlus (adsorptive media system)

- Industrial Reverse Osmosis System (6400 GPD)

11) Troubleshooting table

| Symptom you see | Likely role of phosphate | Companion checks | Practical fix |

|---|---|---|---|

| Slimy film in storage tank or at faucet aerators | Nutrient feeding biofilm | Total coliform/E. coli; orthophosphate trend | Sanitize tank/plumbing; refresh carbon; install POU RO for drinking |

| New landscaping or field fertilization; taste change | Potential surface influence into well | Nitrate/nitrite; orthophosphate; conductivity | Improve wellhead protection and buffer zones; POU RO at the sink |

| Scaling in kettle or RO storage | Ca/Si/PO4 complexes | Hardness; silica; phosphate | Softening + RO; consider antiscalant or specialty media where appropriate |

| Musty/earthy odors | Biofilm/organics (P is a co‑factor) | DOC/TOC (lab), orthophosphate | Catalytic carbon + on‑time filter changes; sanitize; RO for tap |

12) Disclaimers & notes

- This article provides general information and gear suggestions for private well owners. For high or unusual results—or if infants, immunocompromised individuals, or pregnant persons rely on the supply—consult a certified drinking‑water lab and local health/environmental agencies.

- Treatment performance depends on site‑specific water chemistry, flow, temperature, and maintenance. Always confirm equipment claims and re‑test post‑treatment.

- For editorial completeness, consult reputable references such as the EPA’s National Primary Drinking Water Regulations (NPDWR), USGS Water Science School (“Phosphorus & water”), Standard Methods 4500‑P, and EPA Method 365.3.