Legionella in Well Water: The Complete Homeowner’s Guide to Risks, Testing & Treatment

If you rely on a private well, you own your water quality. This in‑depth guide explains what Legionella bacteria are, how they spread, what testing reveals, and which proven treatments—like UV disinfection and chlorination—help keep your household safe. You’ll also find curated product links to WaterSoftenerPlus.com so you can put best practices into action.

- Exposure Legionella are environmental bacteria that become dangerous mainly when they amplify in plumbing and are inhaled as fine mist (e.g., showers, sprayers).

- Temperatures Growth is favored roughly between 20–50 °C (68–122 °F), especially 25–45 °C (77–113 °F). Keep cold water cold and hot water hot.

- Private wells Federal rules don’t regulate private wells; homeowners must test and treat their own water.

- Treatments For microbiological safety, consider NSF/ANSI 55 Class A UV or well‑designed chlorination, with proper pretreatment and maintenance.

- Shock chlorination Use after service, flooding, or a positive bacteria test; always retest a short time after to confirm results.

1) What is Legionella?

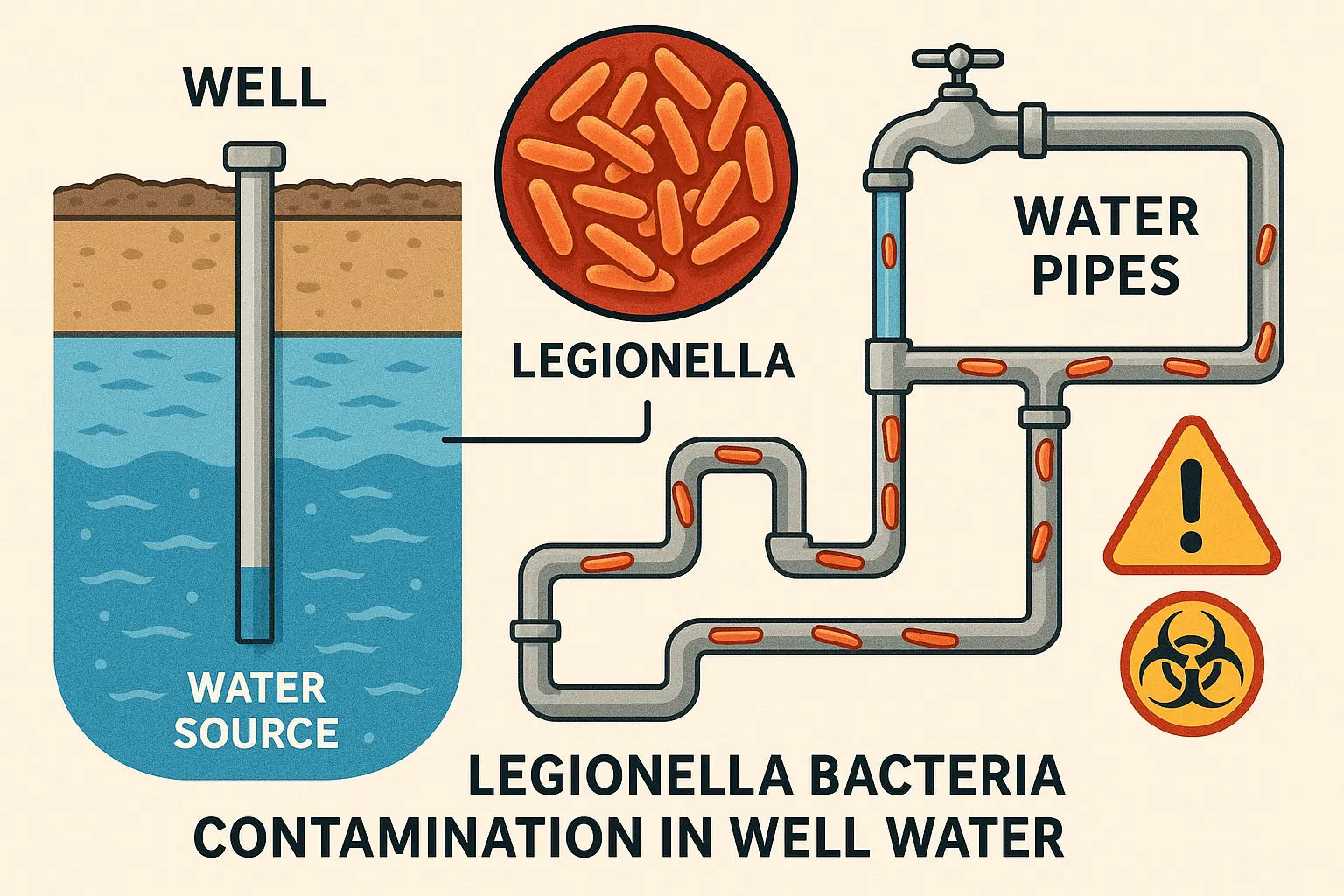

Legionella are Gram‑negative bacteria found widely in natural freshwater and in man‑made water systems. In nature, they typically occur at low concentrations, but they can amplify in building plumbing under the right conditions—warm temperatures, nutrient availability, stagnation, and protective biofilms. The species Legionella pneumophila is most often linked with human disease: Legionnaires’ disease (a serious pneumonia) and Pontiac fever (a milder, flu‑like illness). Legionella can persist within biofilms and inside free‑living protozoa, which shields them from stress and some disinfectants.

Plain‑English version: Legionella live in water. They’re most dangerous not out in lakes or wells by themselves, but when they multiply inside your home plumbing or fixtures and get sprayed into the air as tiny droplets you breathe.

2) How Legionella spreads, who’s at risk, and common exposure points

The overwhelming route of exposure is breathing in aerosolized droplets that contain Legionella—think hot showers, spray wands, humidifiers, decorative fountains, or misters. In some situations, aspiration (water “going down the wrong pipe”) can also expose the lungs. Importantly, Legionella generally does not spread person‑to‑person. People at higher risk of severe illness include adults over 50, smokers, those with chronic lung disease, and anyone who is immunocompromised.

Typical exposure points in and around homes and small buildings include showerheads, hand‑held sprayers, hot tubs, whirlpools, cooling mist systems, and poorly maintained water heaters. These sources combine warmth, stagnation, and aerosolization—the trifecta for increased risk.

Health note: If you ever develop pneumonia‑like symptoms (fever, cough, shortness of breath) after a recent exposure to aerosols (e.g., hot tub, heavy shower mist), seek medical care promptly and mention possible Legionella exposure to your clinician.

3) Private wells, regulation, and what that means for owners

In the United States, water from private domestic wells is not regulated by the federal Safe Drinking Water Act. That means there’s no government agency routinely monitoring, treating, or guaranteeing the quality of your private well water. Responsibility for testing and treatment lies with the homeowner, though local and state health agencies often provide guidance and lab referrals.

Practically, this means two things. First, you should have a baseline and routine testing schedule (more on that below). Second, if you choose to install treatment (e.g., UV disinfection or chlorination), you are responsible for selecting, sizing, installing, and maintaining that equipment—or hiring a qualified professional to do so. Good design and consistent maintenance matter as much as the technology itself.

4) Conditions that let Legionella grow in home well & plumbing systems

Temperature, temperature, temperature

Legionella growth accelerates within a warm range. Health and engineering guidance aligns on a broad band of roughly 20–50 °C (68–122 °F), with a favored window around 25–45 °C (77–113 °F). Keeping cold water cold (ideally under 25 °C/77 °F) and hot water hot (store around 60 °C/140 °F; maintain ≥49 °C/120 °F in circulation) is a cornerstone of risk reduction in buildings—including homes served by private wells. Use thermostatic mixing valves to prevent scalds.

Water age and stagnation

“Water age” is the time water spends sitting in pipes, heaters, or tanks. The longer it sits, the more disinfectant (if any) dissipates, the more temperature equalizes toward room/warm ranges, and the more biofilm can mature—conditions that can favor Legionella growth. Stagnant lines (guest bathrooms, hose bibs, seasonal properties) are especially vulnerable; regular flushing is a simple, powerful control.

Biofilms, sediments, and scale

Legionella often embed in biofilms and can survive inside protozoa. Sediments, iron/manganese deposits, and scale provide “niches” that shelter microbes from flow and some disinfectants. From a homeowner’s perspective, pretreatment that keeps water clear and low in particulates helps any downstream disinfection work much better.

Hot‑water systems are the usual amplifier

While Legionella can enter a home from any freshwater source (including a private well), the amplifier is often the hot‑water system itself—warm, intermittently used, and sometimes set at temperatures that sit right in the bacteria’s comfort zone. That’s why well owners should focus on both the source (well) and the system (plumbing, heater, fixtures).

5) Testing: what to test, when to test, and how results are used

Baseline well testing: start with indicators

For private wells, public‑health agencies recommend routine testing for total coliform and E. coli as indicators of sanitary integrity. If you get a positive result—especially for E. coli—do not drink the water until resolved; consider boiling for cooking and drinking or using an alternative source, and move to corrective actions (e.g., shock chlorination) followed by retesting.

Should homeowners test specifically for Legionella?

Legionella testing is common in complex buildings (hospitals, hotels) as part of a formal water management program. For single‑family homes, it’s usually considered when: (1) someone at home is at higher medical risk, (2) there’s a history of respiratory illness potentially linked to water aerosols, or (3) you are troubleshooting persistent hot‑water temperatures/stagnation issues. If you elect to test, environmental labs can analyze water or swab samples; 250 mL is a typical potable‑water sample volume for routine testing modules.

Interpreting results and acting on them

Whether you test for indicators or Legionella itself, the goal is to inform action: correct defects (well cap, intrusion), optimize temperatures, flush stagnant lines, and if needed, install or service disinfection systems (UV, chlorination). For well disinfection after contamination or maintenance, follow recognized guidance and retest a short time after treatment so residual chlorine is gone and results reflect true water quality.

6) Prevention & control strategies for well owners

Temperature controls that matter

- Set water heater storage ≈ 60 °C (140 °F); maintain circulation ≥ 49 °C (120 °F). Add thermostatic mixing valves at taps/showers to prevent scalds.

- Keep cold water cold—below ~25 °C (77 °F) where feasible; insulate cold lines exposed to heat and reduce long pipe runs past warm equipment.

- Flush low‑use outlets weekly (showers in guest rooms, exterior hose bibs) and after vacations or seasonal closures to reduce water age.

System hygiene and plumbing design

- Remove “dead legs” (capped or unused pipe runs) during remodels.

- Clean or replace showerheads and aerators periodically; mineral buildup harbors biofilm.

- Service well components on schedule (sanitary well cap intact, pitless adapter sealed, vent screened).

- Size pressure tanks and recirculation loops to minimize long idle times.

Pretreatment supports disinfection

For UV or chlorination to do their job, the water needs to be clear and low in turbidity. Sediment filters (e.g., “Big Blue” housings), iron/manganese media (e.g., Katalox Light), and activated carbon (for dechlorination and organics) are common in well systems. Pretreatment is not a luxury—it’s often a requirement in manufacturer specifications for microbial performance.

7) Treatments that work: UV, chlorination, filtration, and more

Ultraviolet (UV) disinfection

What it is: UV systems expose water to germicidal light that inactivates bacteria (including Legionella), many viruses, and protozoa so they cannot reproduce. For drinking water safety on private wells, look for systems certified to NSF/ANSI 55 Class A and ensure they are sized for your peak flow and UV transmittance. Class A systems are intended for treating microbiologically unsafe water and include dose and safety features beyond Class B.

What it needs to work well: Adequate UV dose (reactor sizing), clear water (sediment/iron removal upstream), clean quartz sleeves, timely lamp replacements, and—ideally—monitored units that alarm on low dose. Proper design and the effect of particulates on UV performance are critical.

Popular UV options at WaterSoftenerPlus

VIQUA UV Systems – full collection VIQUA 3 GPM UV System (compact) VIQUA 12 GPM Whole‑Home UV (integrated)

Tip: Install UV as the final stage—after sediment/iron removal—to ensure high UV transmittance and reliable dose delivery.

Continuous chlorination (chemical feed + contact time)

What it is: A metering (chemical feed) pump injects chlorine solution into the water; a contact tank provides time for disinfection; downstream activated carbon removes chlorine taste/odor. This approach can provide ongoing microbial control and also oxidize reduced iron/manganese and sulfide, which are common in wells.

What it needs to work well: Correct dosing, adequate mixing and contact time, and periodic verification (free chlorine testing). If you choose this route, engage a local water professional to size the pump, solution strength, and contact volume for your flow. Activated carbon after the contact tank improves taste and removes by‑products.

Build a chlorination train

Pentek “Big Blue” 10″ Housing Activated Carbon Filters Katalox Light Iron/Manganese Systems

Looking to address sulfur/iron along with microbes? Consider oxidation + filtration or specialized media.

Shock chlorination (one‑time or episodic)

When to use: After well construction/repair, flooding, or a positive bacteria test. Shock chlorination disinfects the well casing, pump, and plumbing using a strong chlorine solution circulated through the system, then flushed. After treatment, retest a short time later to confirm results.

Limitations: Shock chlorination can clear one‑time intrusions, but if contamination keeps returning—or if the hot‑water system sits in the Legionella growth zone—consider continuous controls (temperature correction, UV, or chlorination). Short‑term “shocks” sometimes provide only temporary relief when underlying causes persist.

Filtration & pretreatment (make disinfection work better)

- Sediment filters (e.g., Big Blue housings) remove turbidity that can shield microbes from UV and reduce chlorine demand.

- Iron & manganese media (e.g., Katalox Light, air‑injection filters) reduce staining and fouling that shelter biofilm.

- Activated carbon improves taste and removes chlorine after contact tanks; it is not a stand‑alone disinfectant.

Pretreatment picks for well water

Pentek “Big Blue” 10″ Housing Whole‑House Carbon Katalox Light (Iron/Manganese) Upflow Catalytic Carbon (No‑Electric)

What about water softeners?

Water softeners are excellent for removing hardness minerals (calcium/magnesium) that cause scale and can indirectly contribute to biofilm niches—but softeners do not disinfect. If you need microbial protection, pair softening with UV or chlorination.

Choosing between UV and chlorination

- UV (NSF 55 Class A): Chemical‑free, instant inactivation, no taste change; requires clear water and power; no residual in piping.

- Chlorination (POE): Provides a residual and oxidizes certain inorganics; adds taste/odor without carbon; requires contact time and chemical handling.

- Hybrid (UV after filtration; optional low‑dose chlorination ahead of storage tanks): Common on complex or seasonally used systems.

8) A 90‑day action plan to harden your well & plumbing against Legionella

Days 1–7: Assess & test

- Visually inspect your wellhead: sanitary cap intact, vent screened, no ponding water nearby.

- Note hot‑water setpoint on the heater and measure temperatures at a distant tap after full warm‑up.

- Sample your well water for total coliform/E. coli to confirm sanitary integrity.

- List low‑use fixtures; plan a weekly flushing routine for them.

Days 8–30: Fix the basics

- Set the water heater storage temperature to ~60 °C/140 °F; install thermostatic mixing valves to prevent scalding.

- Clean/replace showerheads and aerators; remove dead‑legs during any remodels.

- Establish a weekly flushing plan (2–5 minutes per seldom‑used tap, until water runs hot or cold as intended).

Days 31–60: Choose and install disinfection

- Size and install pretreatment (sediment, iron/manganese) based on your lab results and flow needs.

- Select a Class A UV system or design a chlorination + contact + carbon train; place UV as the final stage, after filtration.

Days 61–90: Verify & maintain

- If you performed shock chlorination, retest 7–10 days after treatment.

- Log maintenance: UV lamp/sleeve service dates; chlorine strength and residual checks; filter changes.

- Keep temperatures and flushing on schedule—simple behaviors that pay dividends.

9) Bacteria 101: Legionella vs. other well water microbes

Private wells can encounter a range of bacteria. Total coliform and E. coli are general indicators of fecal contamination; their presence suggests a sanitary failure (surface intrusion, well construction problems) and warrants immediate corrective action. Legionella differs in that it is chiefly a plumbing‑system amplifier: it thrives in warm, stagnant areas and causes disease mainly when inhaled as tiny droplets. An E. coli positive tells you “fix your well and retest.” A Legionella concern tells you “fix your system (temperatures, stagnation) and consider continuous disinfection.”

10) Myths & facts

Myth: “If my well tests negative for coliform, I can’t have Legionella.”

Fact: Coliforms are indicators of fecal contamination, not a complete inventory of environmental bacteria. Legionella can still colonize warm plumbing systems that are otherwise coliform‑free.

Myth: “Lowering my water‑heater setpoint saves energy and reduces scalding; it’s safer in all ways.”

Fact: Lower setpoints can land in the Legionella growth range. The safer strategy is high storage temperature with mixing valves at outlets to prevent scalds while maintaining microbial control.

Myth: “A water softener disinfects my water.”

Fact: Softeners remove hardness; they do not disinfect. Pair softeners with UV or chlorination for microbiological protection.

11) Frequently asked questions

- Can Legionella live in cold water?

- Yes—growth is slower, but Legionella can survive at lower temperatures and grow more rapidly as water warms into the 20–50 °C (68–122 °F) range.

- Is Legionella spread by drinking water?

- Illness usually results from inhaling aerosolized droplets (e.g., shower mist). Drinking water that goes to the stomach is not the typical route for legionellosis, although aspiration events can pose a risk.

- Do I need to test specifically for Legionella?

- Most single‑family homes start with indicator testing (total coliform/E. coli) to assess sanitary integrity. Consider Legionella testing if you have high‑risk occupants or persistent system conditions that favor growth. In large buildings, routine Legionella testing is a tool for verifying water‑management programs.

- What hot‑water settings should I use?

- Store at ~60 °C/140 °F; maintain distribution ≥49 °C/120 °F; use thermostatic mixing valves at taps and showers to prevent scalds.

- Is UV enough?

- UV can provide robust microbiological protection when properly sized, installed, and maintained—and when water is clear. Pair UV with pretreatment (sediment/iron removal). For some systems, chlorination (with contact time and carbon) may be preferred or used in combination.

- How long after shock chlorination should I wait to retest?

- Seven to ten days is a common interval to ensure residual chlorine is flushed and results reflect steady‑state conditions.

12) Shop proven solutions at WaterSoftenerPlus

Disinfection & pretreatment

VIQUA UV Systems – Collection VIQUA 3 GPM UV System VIQUA 12 GPM Whole‑Home UV Pentek “Big Blue” 10″ Housing Whole‑House Activated Carbon Katalox Light Iron/Manganese Upflow Catalytic Carbon Filter Coconut Shell Catalytic Carbon

Need a tailored setup? Start with pretreatment (sediment/iron), then add Class A UV as the final stage—or design a chlorination + contact + carbon train.

13) Important safety & medical disclaimer

This article is for educational purposes and is not medical advice. Legionnaires’ disease is a serious pneumonia; if you’re ill or high‑risk (age ≥50, chronic lung disease, immune compromise), seek clinical care and mention any potential water‑aerosol exposures. Installation of treatment equipment involves electrical, plumbing, and chemical safety—hire qualified professionals when in doubt. Follow manufacturer instructions and applicable local codes.

14) References (selected)

- Centers for Disease Control and Prevention (CDC) — Legionella overview, transmission, and risk factors. CDC Legionella

- World Health Organization (WHO) — Legionellosis fact sheet and water system guidance. WHO Fact Sheet

- U.S. Environmental Protection Agency (EPA) — Private wells and homeowner responsibilities. EPA Private Wells

- NSF International — UV disinfection (NSF/ANSI 55) consumer overview. NSF UV