Campylobacter in Well Water: The Complete Homeowner’s Guide to Testing, Disinfection & Prevention

If your family relies on a private well, you are effectively your own water utility. This long‑form, SEO‑optimized guide explains—plainly and practically—what Campylobacter is, how it gets into groundwater, what symptoms and risks to watch for, how to sample and test correctly, when to boil or shock‑chlorinate, and which whole‑home and point‑of‑use treatments create a robust microbiological barrier. We’ve also included curated product links to WaterSoftenerPlus.com so you can move from “problem” to “solution” with confidence.

Fast Answer: What to do today if you suspect bacteria

- Do not drink, cook, make ice, or brush teeth with untreated tap water. Use bottled water or boil your water at a full, rolling boil for 1 minute (or 3 minutes above 6,500 feet).

- Arrange a bacteria test with a state‑certified lab: request total coliform and E. coli. Add nitrates, TDS, and pH for a basic health check. Test again after any disinfection.

- If results show E. coli or you have reason to believe fecal contamination is present, take the system out of service for consumption and perform shock‑chlorination; then flush and retest.

- Install a permanent barrier: a whole‑home UV disinfection system at the point of entry (POE), and a reverse osmosis or ultrafiltration system at the kitchen sink (POU) for drinking water.

Fast, proven solutions

- Whole‑Home UV Water Sterilization — chemical‑free microbiological disinfection for every tap.

- Under‑Sink Reverse Osmosis Systems — bottled‑quality drinking water at your sink.

- Pentek Big Blue Sediment Prefilter — protect UV and RO with proper pre‑filtration.

Note: Softeners do not kill bacteria; pair hardness treatment with UV/RO/UF.

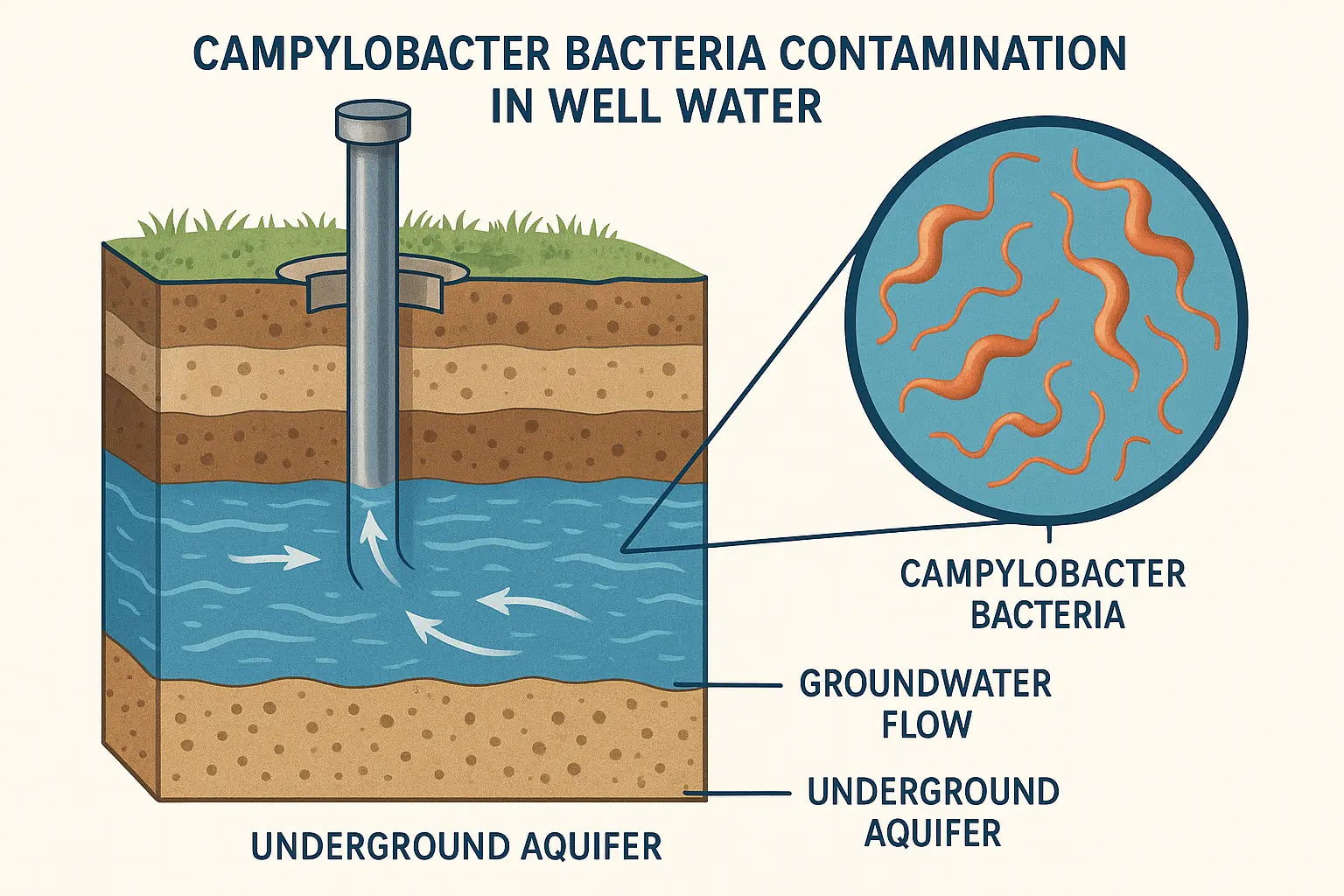

What is Campylobacter?

Campylobacter is a genus of spiral‑shaped, Gram‑negative bacteria. The species most often linked to human illness is Campylobacter jejuni, with C. coli also implicated. While most cases of campylobacteriosis are foodborne—especially from undercooked poultry—waterborne transmission is well documented. Private wells can be vulnerable because they are not overseen by a public utility; homeowners are responsible for monitoring, maintenance, and treatment.

Campylobacter is microaerophilic (prefers reduced oxygen) and can persist in cool water and within biofilms. Even relatively low doses of organisms may cause illness, which is why a robust multi‑barrier approach—source protection, disinfection, and point‑of‑use polishing—matters so much for households on well water.

Symptoms, risks & who is most vulnerable

Campylobacter typically causes gastrointestinal illness. Common symptoms include diarrhea (which may be bloody), abdominal cramps, fever, nausea, and general fatigue. Symptoms usually develop 2–5 days after exposure and can last about a week. Most healthy adults recover with rest and hydration, but there are important risk considerations:

- Young children and older adults are more vulnerable to dehydration and complications.

- People who are pregnant, immunocompromised, or managing chronic conditions can experience more severe illness.

- In rare cases, complications such as reactive arthritis or neurological syndromes may follow infection. Anyone experiencing persistent or severe symptoms should seek medical care.

Important: This article is educational and not a substitute for medical advice. If someone in your home has severe diarrhea, signs of dehydration, high fever, or blood in stool, speak with a clinician.

How Campylobacter enters private wells

Understanding pathways helps you prevent them:

- Heavy rainfall and flooding: Intense precipitation can drive surface water—containing animal or human fecal material—into shallow aquifers or directly down poorly sealed well casings and caps.

- Septic system leakage or poor setbacks: Failing tanks or drainfields, or siting a well too close to a septic system, can introduce pathogens.

- Well construction defects: Missing sanitary seals, cracked casings, ungrouted annular space, and uncapped vents can allow insects and contaminated runoff to enter.

- Animal yards and manure storage: Livestock pens, kennels, and wildlife activity near the wellhead raise the fecal load in runoff.

- Plumbing dead‑legs and biofilms: Low‑flow sections of household plumbing can harbor biofilms that protect bacteria from disinfectants and allow regrowth if barriers are absent or fail.

Practical signs your well may be at risk

- After storms: Water turns cloudy or has a change in taste/odor.

- Infrastructure changes: Recent pump service, well repair, or plumbing work without post‑service disinfection.

- Septic indicators: Surfacing effluent, backups, or foul odors around the drainfield.

- Proximity issues: Short setbacks from septic fields, livestock areas, or manure storage.

- History of coliform positives: Repeated positive tests suggest a structural vulnerability that needs correction.

Testing: what to test, how to sample, and how to read results

What to test

Homeowners typically start with indicator bacteria rather than testing directly for Campylobacter:

- Total coliform bacteria (presence suggests a sanitary breach somewhere in the system).

- E. coli (a fecal indicator that is a stronger red flag for contamination that can carry pathogens).

- Also helpful: nitrates (especially important for infants), total dissolved solids (TDS), and pH.

Indicator results guide your next steps. A positive total coliform doesn't name the pathogen—but it tells you the door is open for microbes, so act and investigate.

How to collect a clean sample

- Use a state‑certified laboratory. Request their sterile bottle and follow their instructions exactly.

- Choose a sampling tap that represents water coming into the house. Bypass filters and softeners unless you’re intentionally testing treated water.

- Remove aerators and attachments. Run cold water for 2–3 minutes.

- Wash your hands. Do not touch the inside of the bottle or cap. Fill to the line, recap immediately.

- Keep the sample cold (refrigerated or on ice) and deliver it to the lab within the specified time window.

Interpreting results (plain‑English flow)

- No total coliform detected: Great news. Keep up annual testing and basic prevention.

- Total coliform detected, no E. coli: There is a sanitary breach. Investigate sources, consider shock‑chlorination, and retest. Install or verify your permanent barrier.

- E. coli detected: Treat as a serious contamination event. Use boiled or bottled water for consumption, disinfect the system, flush, and retest. Keep a permanent barrier in place.

Helpful tools from Water Softener Plus

- Step‑by‑Step Water Testing Procedures (Guide)

- Pentek Big Blue 10″ Housing + Cartridges — ideal pre‑filter before UV/RO.

Tip: Decide whether you are testing raw water (before treatment) or finished water (after treatment). You may want both views.

Immediate actions (boiling & shock‑chlorination)

Boiling

Bring water to a full, rolling boil for at least 1 minute (or 3 minutes above 6,500 ft). Use boiled water for drinking, cooking, brushing teeth, washing produce, making baby formula, and for ice until your system is disinfected and post‑treatment tests are clean.

Shock‑chlorination (high‑level disinfection)

When to use: After flooding, positive bacteria tests, well servicing, or new‑well commissioning. Shock‑chlorination is a one‑time, high‑dose disinfection to sanitize the well, pump, drop pipe, pressure tank, and plumbing.

Safety first: Wear eye protection and gloves. Never mix chlorine with acids or ammonia. Provide ventilation, and protect septic systems from excessive bleach discharge by following measured doses and flushing in stages.

Step‑by‑step overview

- Power off the pump. Remove the well cap or seal carefully.

- Calculate dose. As a general homeowner rule of thumb (not a substitute for manufacturer tables), you can target >100 mg/L free chlorine in the water column. For example, many disinfection tables advise adding about ½–1 gallon of standard household bleach (5–6% sodium hypochlorite) per 100 feet of water in a 6‑inch casing. Always verify against your casing diameter and water column height.

- Introduce chlorine evenly into the well, and use a clean hose to circulate water back into the casing for 15–30 minutes to mix thoroughly.

- Open each tap in the home until you smell chlorine, then close. Do the same for outdoor spigots. Don’t forget the water heater (turn it to vacation/low while disinfecting).

- Contact time: Allow the system to sit for 8–12 hours (overnight).

- Flush to waste outside (away from plants and septic) until chlorine odor diminishes; then continue flushing through interior fixtures until chlorine is gone.

- Retest in a few days (your lab will recommend timing). If results remain positive, investigate structural issues and consider repeating disinfection.

Good practice: Even with successful shock‑chlorination, install a permanent disinfection barrier so you’re protected against future events you can’t predict—like storms or disturbed soil.

Permanent treatments that work (UV, RO, UF)

1) Whole‑home UV disinfection (POE)

How it works: UV light damages microbial DNA/RNA as water flows past the lamp, inactivating bacteria, viruses, and protozoa. It does not use chemicals, and it leaves no residual taste or odor.

Why whole‑home: When installed at the point of entry, UV treats the entire house—kitchen, baths, laundry, and outdoor spigots—protecting plumbing from bacterial growth.

What to look for: Systems marketed for microbiologically unsafe water often align with rigorous validation criteria (e.g., dose monitoring/alarms). Confirm the unit is sized for your peak flow and that you have proper pre‑filtration so turbidity and color don’t “shade” microbes from the UV lamp.

Recommended UV options

- UV Water Sterilization System (Whole‑Home) — install after sediment filtration and before softening.

- Browse UV Systems & Bundles

Maintenance: replace lamps annually, clean quartz sleeves, and keep a spare lamp/o‑rings on hand.

2) Reverse osmosis (POU)

How it works: RO uses a semi‑permeable membrane to remove dissolved salts, metals, and microorganisms. It’s an ideal “last mile” barrier at the kitchen sink for water you ingest.

Why add RO if you have UV? UV inactivates microbes; RO removes them and improves taste by reducing TDS. Together they create redundancy.

RO picks for the kitchen

- Under‑Sink RO Systems — compact, efficient drinking water solutions.

- Nimbus Sierra Alkaline RO (50 GPD) — classic multi‑stage format with remineralization.

Tip: Connect RO to your fridge/ice for consistent cooking and beverage quality.

3) Ultrafiltration (POU)

How it works: UF membranes or absolute‑rated bacterial filters physically remove bacteria at the micron/sub‑micron level. They don’t typically reduce dissolved salts like RO does, but they maintain flow and keep beneficial minerals.

Use cases: Where you want high flow without a storage tank, or as a post‑carbon polishing step for taste and microbial safety.

4) Boiling and continuous chlorination

Boiling is the universal emergency option. Continuous chlorination (metered injection with contact time and carbon polishing) can be used where UV is impractical, but it adds taste/odor and requires monitoring. Many homeowners prefer UV at POE plus RO at POU.

Supporting components

- Pentek Big Blue Sediment Filter — ensures clear water so UV can “see” microbes and protects RO membranes.

- Iron & Sulfur Whole‑House Filter — reduce iron, manganese, and sulfur that can foul UV sleeves and appliances.

Remember: A water softener does not disinfect; it should be paired with UV/RO when hardness is present.

System design: sizing, placement & maintenance

1) Sizing UV correctly

- Flow rate: Choose a UV unit rated for your peak household flow (e.g., 10–12 GPM for many 3–4 bedroom homes). If you have high‑flow fixtures or multiple bathrooms, upsize.

- UV transmittance (UVT): High color/turbidity can reduce effectiveness. Pre‑treat with sediment (and often carbon) so UV can work properly.

- Monitoring: Look for systems with alarms/shutoff for lamp failure or low dose.

2) Where to place each component

- Incoming line → sediment filter → carbon (if needed for taste/odor) → UV (POE) → softener (if desired) → house distribution.

- Kitchen sink (POU) → tee off cold line to RO or UF → dedicated faucet → optional fridge/ice line.

3) Maintenance intervals

| Component | Typical Interval | What to do |

|---|---|---|

| Sediment pre‑filter | 3–6 months (or by pressure drop) | Replace cartridge; keep spares on hand. |

| Carbon filter | 6–12 months | Replace cartridge; prevents taste/odor and protects UV sleeves from organics. |

| UV lamp | 12 months | Replace lamp; clean or replace quartz sleeve as needed. |

| RO prefilters | 6–12 months | Replace sediment and carbon stages. |

| RO membrane | 24–36 months (feed‑water dependent) | Replace when TDS rejection falls or flow declines. |

| UF membrane | 12–24 months | Replace per manufacturer or when flow declines. |

4) Water chemistry that affects performance

- Iron & manganese: Stain fixtures, foul quartz sleeves, and reduce UV efficacy—treat with dedicated media or oxidation/filtration.

- Hydrogen sulfide: Causes odor and can interfere with oxidation and some media—treat upstream.

- Hardness: Forms scale on heating elements and quartz sleeves—soften after UV or use anti‑scale strategies.

- Tannins/color: Reduce UVT—carbon or specialized resins may be needed.

Workflow for success: Test → fix structural issues → disinfect → install multi‑barrier treatment → set reminders to maintain → retest annually and after major weather events or repairs.

Prevention & wellhead housekeeping

- Protect setbacks: Keep wells an appropriate distance from septic systems and animal areas; follow your state or local codes.

- Harden the wellhead: Use a sanitary cap with intact screens; extend casing above grade; grade the surface to shed water away.

- Seal pathways: Ensure the annular space is properly grouted; repair cracks in casings.

- Manage runoff: Divert roof and yard drainage; store manure responsibly; fence off livestock from the immediate well area.

- Plan for weather: After heavy rain or flooding, assume risk is elevated—boil for consumption and retest before returning to normal use.

Myths vs facts

-

Myth: “If my water looks and tastes fine, it’s safe.”

Fact: Many microbes are invisible. Only testing and proper barriers confirm safety. -

Myth: “A water softener removes bacteria.”

Fact: Softeners remove hardness minerals; they do not disinfect water. -

Myth: “I shocked the well once; I’m good forever.”

Fact: Shock‑chlorination is a one‑time sanitation step, not a permanent barrier. Install UV and POU protection for ongoing safety. -

Myth: “A fridge filter/pitcher protects me from pathogens.”

Fact: Most are not rated for bacterial removal. Use UV/RO/UF for microbiological control.

Troubleshooting common issues

1) UV alarm or low dose warning

- Check for lamp age; replace if at or beyond 12 months of run time.

- Inspect and clean the quartz sleeve; replace o‑rings; verify power supply.

- Evaluate pre‑filters: clogged or undersized filters drop pressure and flow.

- Assess UVT: If water is colored/turbid, add/upgrade pre‑treatment.

2) Recurrent total coliform positives

- Look for structural issues: loose cap, cracked casing, or unsealed conduits.

- Disinfect and flush the entire plumbing, not just the well.

- Replace old filter housings; sanitize refrigerator lines and icemakers.

- Confirm UV is installed before distribution and operating correctly.

3) RO tastes “flat” or “too pure”

- Add a remineralization cartridge or blend a small amount of filtered (non‑RO) water to adjust taste.

- Replace prefilters on schedule; a tired carbon stage can affect flavor.

Budget & cost of ownership (typical homeowner ranges)

| Item | Upfront | Annual Ongoing | Notes |

|---|---|---|---|

| POE UV system | $$–$$$ | $ (lamp + sleeve maintenance) | Choose a unit sized for peak flow; keep spare lamp on hand. |

| Under‑sink RO | $–$$ | $ (prefilters) + $ (membrane every 2–3 years) | Optional remineralization stage for taste. |

| UF/absolute bacterial filter | $–$$ | $ (cartridge replacement) | Verify absolute rating (e.g., ≤0.3 µm). |

| Sediment pre‑filter | $ | $ (cartridges) | 5‑micron is a common starting point; adjust for your water. |

| Carbon filtration | $ | $ (cartridges) | Improves taste/odor and UVT. |

| Iron & sulfur treatment | $$–$$$ | $ (media/service) | Protects UV sleeves and appliances; improves overall quality. |

| Annual lab testing | $ per test | $–$$ | Do at least annually, plus after storms or repairs. |

Key: $ ≈ lower cost, $$ ≈ mid, $$$ ≈ higher. Exact pricing varies by brand, flow, and local installation rates.

Downloadable checklists

- Sanitary cap sealed; vent screen intact; casing extends above grade.

- Graded pad sheds water away; no ponding near the well.

- Animal activity controlled; manure stored away from well.

- Septic tank and drainfield inspected per local guidance; no surfacing effluent.

- POE UV lamp under 12 months old; sleeve clear; alarms clear.

- Filter cartridges replaced on time; pressure normal; no leaks.

- Flush seldom‑used taps to limit stagnation and biofilm formation.

- Total coliform & E. coli (lab); consider nitrates, TDS, pH.

- After heavy rain/flooding or repairs: retest before normal use.

- Maintain a file with results, maintenance dates, and parts replaced.

- Boil for consumption uses (1 minute; 3 at elevation).

- Collect bacteriological sample; contact local health department if needed.

- Shock‑chlorinate; flush; retest.

- Verify/Install permanent barriers (UV at POE; RO/UF at POU).

Frequently asked questions

Is Campylobacter really a concern in private wells?

Yes. While food is the most common source of exposure, wells can become contaminated via rainfall events, failing septic systems, or construction defects. Because private wells aren’t regulated like municipal systems, proactive testing and permanent barriers are critical.

Do I need both whole‑home UV and under‑sink RO?

They address different goals. UV inactivates microbes throughout the house; RO removes microbes and many dissolved substances for drinking and cooking. Many well owners choose both for resilience and quality.

What about ultrafiltration instead of RO?

UF removes bacteria and retains minerals, often with higher flow and no storage tank. RO removes a broader range of dissolved contaminants but wastes a small amount of water during production. Your choice depends on goals and feed‑water quality.

How often should I replace UV lamps?

Typically every 12 months. Lamp intensity declines with hours of use even if the lamp still “glows.” Keep your quartz sleeve clean and replace o‑rings when servicing.

Can I install UV before the softener?

Best practice is sediment → (optional carbon) → UV → softener → house. Many homeowners install UV before softening so the entire home, including the softener, receives disinfected water.

Will a pitcher filter protect my family from Campylobacter?

Most pitcher filters are not designed or certified for bacterial removal. Use UV, RO, or UF for microbiological protection.

What is “absolute” vs “nominal” micron rating?

An absolute rating means the filter’s pores are small enough to block particles at or below the stated size with high confidence. A nominal rating is looser and may allow some particles to pass. For bacteria removal, choose absolute ratings (e.g., ≤0.3 µm).

Do I still need to test if I have UV/RO?

Yes. Treatment is most effective with monitoring. Test annually, plus after major storms or any service to the well or plumbing.

Why you can trust these recommendations

This guidance reflects standard, field‑tested practices for private wells: using indicator bacteria to assess sanitary integrity; boiling and shock‑chlorination for emergencies; and multi‑barrier treatment with whole‑home UV and point‑of‑use RO/UF for daily protection. Combine prevention at the wellhead with maintenance schedules and regular testing to keep your household safe year‑round.

Build your multi‑barrier setup (curated components)

| Barrier / Role | Why it matters | Recommended at WaterSoftenerPlus |

|---|---|---|

| POE UV disinfection | Whole‑home inactivation of bacteria/viruses at every tap. | UV Water Sterilization System |

| Pre‑filtration (sediment) | Ensures clear water so UV can “see” microbes; protects RO membranes. | Pentek Big Blue 10″ Housing + Cartridges |

| POU drinking water | Second barrier at the tap; removes microbes & improves taste. | Under‑Sink Reverse Osmosis Systems |

| Iron / Sulfur management | Prevents fouling of UV sleeves & appliances; improves taste/odor. | Iron & Sulfur Whole‑House Filter |

| All products | Browse bundles and compatible accessories. | Shop All |