Microplastics in Drinking Water: The Complete Guide to Risks, Testing, and Proven Home Filtration

From bottled water headlines to tap-water studies, “microplastics” have become the latest reason families and cafés are upgrading their filtration. This guide explains what microplastics are, how they get into your water, the practical risks, and the exact multi‑stage systems that remove them—so you can choose confidently and drink better, starting today.

Paste Parts 1–4 in the HTML editor. Links use absolute URLs + data-href for Shopify safety.

1) What Are Microplastics? (and Nanoplastics)

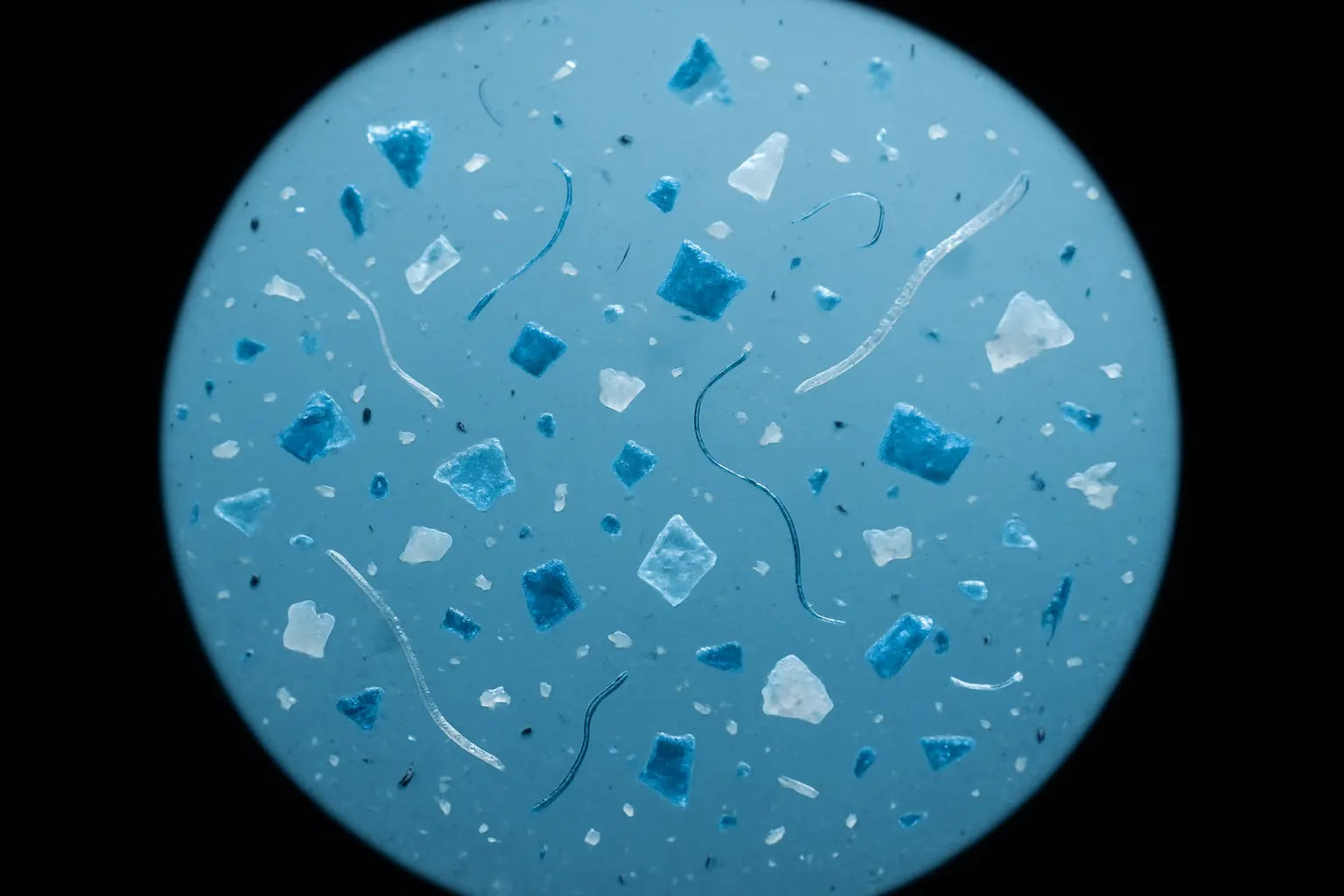

Microplastics are small plastic particles typically defined as less than 5 millimeters in size. That’s a big range—from confetti‑like fragments visible to the eye down to particles so tiny you can’t see them.

For this guide we’ll use three practical buckets that matter for filtration:

- Macroplastics > 5 mm — the stuff you can see (flakes, beads)

- Microplastics 1 µm to 5 mm — visible to sub‑visible particles

- Nanoplastics < 1 µm — ultra‑fine particles bordering molecular scale

Because microplastics vary in shape (fibers, fragments, films, beads) and chemistry (PET, PE, PP, PS, PVC, etc.), capture requires a combination of mechanical filtration (physical sieving/adsorption) and barrier processes (reverse osmosis and, in some setups, nanofiltration/ultrafiltration).

2) Where Microplastics Come From: Everyday Sources

Household & Consumer Sources

- Synthetic clothing fibers released in laundry rinse

- Food/packaging fragments from cutting, heating, or abrasion

- Personal care microbeads (less common now but legacy persists)

- House dust (polymer fibers shed from textiles and carpets)

Outdoor & Infrastructure Sources

- Tire wear particles washed from streets into storm drains

- Paint flakes (marine/industrial) carried by runoff

- Fragmentation of litter in sunlight/heat over time

- Degradation of plastic components in distribution systems

Wastewater plants remove a large share of larger particles, but the smallest fractions can pass through and enter rivers, reservoirs, or groundwater. In distribution, turbulence and aging materials can further fracture particles that reach your tap.

3) How Microplastics Enter Drinking Water

Microplastics take multiple routes into the water you drink and cook with:

- Surface water: Stormwater and wastewater effluent carry particles into rivers and lakes that supply treatment plants.

- Groundwater: Leachate from landfill sites and soil percolation introduce smaller fragments and fibers into aquifers.

- Distribution system: Old plastic components (gaskets, liners) can shed particles; pressure events may dislodge deposits.

- Bottled water: Packaging and bottling lines can contribute particles—filtering at home protects you regardless of brand variability.

4) Why It Matters: Practical Health & Home Risks

Scientists are still investigating long‑term health impacts of microplastics and nanoplastics. Here’s what is practical and non‑alarmist:

- Particles as carriers: Plastics can adsorb other substances (like hydrophobic organics) on their surfaces. Keeping particles out reduces potential “hitchhiker” exposure.

- Inflammation potential: As with fine dust, persistent tiny particles can irritate tissues if exposure is chronic—another reason to minimize ingestion and aerosolized exposure (showers, sprays) when feasible.

- Taste/clarity: Even when invisible, particles can influence water aesthetics and ice clarity.

Beyond personal health, microplastics can settle in appliances (ice makers, kettle elements, espresso boilers), contributing to residue that requires extra cleaning over time. Filtration pays off in fewer maintenance headaches.

5) Testing Basics: What You Can (and Can’t) Measure at Home

There is no single “microplastics test strip.” Most at‑home kits don’t directly speciate plastic particles—laboratories use specialized filtration, staining, and spectroscopy (e.g., FTIR/Raman). Still, you can learn a lot with a practical test plan:

Smart DIY Testing Plan

- TDS & Turbidity: Track baselines; unusual spikes can signal particle or colloid loads (not specific to plastics but useful trend flags).

- Microscopy snapshots: Some labs offer mail‑in microplastics screens; if your region is a hotspot, consider one baseline lab test.

- Before/After checks: Measure taste/odor and clarity before and after installing an RO + carbon system; many customers notice immediate improvements.

Bottom line: For day‑to‑day confidence, invest in proven removal technology (see next section). Lab testing is optional for most households but helpful if you’re in a known risk area or running a business (café, daycare) that needs documented water quality.

6) Removal Overview: Filters That Actually Work (and Why)

No single filter solves everything. The best microplastics strategy uses layered defenses so each stage does what it’s best at:

Sediment & Carbon Block (Nominal Sub‑Micron)

- Sediment Prefilter (1–5 µm): Captures larger fibers/fragments to protect fine stages.

- Carbon Block (0.5–1 µm nominal): Adsorbs organics and traps sub‑micron particles; also improves taste and odor.

Reverse Osmosis (RO)

- Barrier membrane with extremely tight pores; excellent at reducing micro‑ and nano‑scale particulates.

- Also reduces a wide array of dissolved contaminants—an advantage over particle‑only filters.

- Pairs with a dedicated faucet and can feed fridge/ice for crystal‑clear cubes.

For whole‑home protection, a backwashing carbon tank (often catalytic carbon) combined with quality sediment filtration lowers particulate loads across the house, while a point‑of‑use RO at the kitchen sink ensures your drinking and cooking water hits bottled‑quality standards.

7) Buyer Profiles: Fast Picks for Homes, Offices & Cafés

Family Kitchen (Most Popular)

- Under‑sink RO (75–200 GPD) + tank

- Sediment (5 µm) → Carbon block (0.5–1 µm) → RO membrane → Post‑carbon

- Optional tee to fridge/ice for clearer cubes

Apartment / Office

- Countertop RO with integrated carbon block

- No drilling; quick installs; compact footprint

- Annual filter kit swap keeps performance high

Coffee & Tea Programs

- Under‑sink RO + tailored post‑filter for taste balance

- Stable extraction; less sludge in kettles and boilers

- Optional remineralization for a clean, balanced cup

Unsure where to start? Send us your household size, current filter model (if any), and whether you want to feed the fridge/ice line—our team will recommend a right‑sized kit.

8) Filtration Science 101: How Filters Capture Microplastics (and Why RO Wins)

To remove particles you can’t see, you need to understand the mechanisms that trap them. Real‑world filters use a combination of physics and chemistry:

Mechanical Capture

- Sieving: The classic “screen‑door” effect—pores smaller than the particle stop it. Works for larger microplastics (≥1–5 μm) with tight sediment/carbon blocks.

- Inertial Interception: Particles riding the flow can’t make tight turns through tortuous pore paths, so they impact and stick.

- Brownian Diffusion: Ultrafine particles (sub‑micron) bounce randomly and collide with pore walls, improving capture in dense carbon blocks and RO pre‑filters.

Adsorptive & Electrostatic Effects

- Adsorption: Activated carbon’s massive surface area (hundreds of m²/g) grabs hydrophobic compounds on particle surfaces.

- Electrostatic attraction: Surface charges on media and plastics can help bind otherwise “slippery” nano‑fragments long enough to be flushed or trapped downstream.

- Barrier Separation (RO/NF): Reverse osmosis (≈0.0001 μm equivalent) is a near‑absolute barrier for microplastics and strongly reduces nanoplastics.

9) Technology Comparison: What Each Stage Does (and Doesn’t)

| Stage | Typical Pore / Action | Microplastics | Nanoplastics | Other Benefits | Notes |

|---|---|---|---|---|---|

| Sediment Filter | 1–5 μm nominal (depth) | Good for fibers/fragments ≥5 μm | Limited | Protects carbon & RO from clogging | Replace 6–12 months or when pressure drops |

| Carbon Block | 0.5–1 μm nominal + adsorption | Very good for sub‑micron particles | Limited to partial | Removes taste/odor, organics, chlorine | Dense blocks improve particle capture |

| Ultrafiltration (UF) | ~0.01–0.1 μm | Excellent for most microplastics | Partial (upper nano) | High flow, no tank needed | Does not remove dissolved TDS |

| Nanofiltration (NF) | ~0.001 μm | Outstanding | Good | Reduces hardness & some TDS | Less common residentially vs RO |

| Reverse Osmosis (RO) | ~0.0001 μm barrier | Near‑complete | Strong reduction | Removes PFAS, metals, nitrates, etc. | Gold standard for drinking water |

10) Product Spotlights & Proven Configurations

🏠 Under‑Sink RO + Carbon Block (Family Kitchen “Gold Standard”)

Our most popular setup for microplastics and overall water quality. Stages: 5 μm sediment → 0.5–1 μm carbon block → RO membrane → post‑carbon polish. Feeds a dedicated faucet and can tee to the fridge/ice line.

- Removes particles you can’t see and the dissolved contaminants you can’t taste

- Crystal‑clear ice and better tasting coffee/tea

- DIY friendly; typical install under 1–2 hours

🏢 Countertop RO (Apartments & Offices)

Plug‑and‑pour convenience with integrated sediment/carbon pre‑filters and an RO membrane inside the housing. No drilling or plumbing changes required.

- Perfect for renters and small offices

- Annual filter kit maintains peak performance

- Compact footprint; looks great on a counter

☕ RO + Taste‑Tuned Post‑Filter (Coffee/Tea Programs)

For cafés or passionate home brewers, pair under‑sink RO with a taste‑tuning post filter or remineralizer for stable extraction and a sweeter cup.

Shop Post‑Filters & Remineralizers🏠 Whole‑Home Sediment + Carbon (House‑Wide Particle Reduction)

A backwashing carbon tank with quality sediment pre‑filtration lowers particulate load everywhere (showers, laundry, dishwasher). Add a point‑of‑use RO at the kitchen for perfect drinking water.

11) Sizing Your System: Flow, Storage, and Filter Capacity

The right size avoids pressure drops and extends filter life. Use the tables below to pick an RO membrane, storage tank, and cartridges that match your household or business.

11.1 RO Membrane & Tank Sizing (Point‑of‑Use)

| Use Case | Household / Users | RO Membrane | Storage Tank | Notes |

|---|---|---|---|---|

| Apartment / Solo | 1 person | 50–75 GPD | 2–3 gal | Feeds faucet; occasional cooking |

| Family Kitchen | 2–4 people | 100–200 GPD | 3.2–4 gal | Faucet + fridge/ice line |

| Large Family / Entertaining | 5+ people | 300 GPD + | 4–6 gal | Add booster pump if pressure is low |

| Café / Office | 5–25 staff | 300–600 GPD | 4–10 gal | Consider dual tanks for peak service |

11.2 Prefilter Selection (Sediment + Carbon)

| Water Quality | Sediment Micron | Carbon Type | Change‑Out Guide | Tips |

|---|---|---|---|---|

| Municipal (low sediment) | 5 μm | 1 μm carbon block | 6–12 months | Protects RO, improves taste |

| Well (moderate sediment) | 5 μm depth → 1 μm | 0.5–1 μm carbon block | 3–6 months (sediment) / 6–12 (carbon) | Consider dual‑stage sediment if silt is visible |

| High turbidity | 10 μm → 5 μm → 1 μm | 0.5 μm carbon block | As needed by pressure drop | Add whole‑home pre‑filtration |

12) Installation Best Practices: Under‑Sink RO & Whole‑Home Carbon

Whether DIY or professional, a clean install protects performance and prevents leaks.

Under‑Sink RO (Point‑of‑Use)

- Plan the layout: Mount bracket level; confirm tank, faucet, and drain line routes.

- Shut off cold feed and relieve pressure. Use a proper angle‑stop adapter—not a self‑piercing saddle if local codes restrict them.

- Connect stages: Sediment → carbon → RO membrane → post‑carbon → faucet. Observe flow arrows on cartridges.

- Flush: Rinse prefilters for 3–5 minutes; then fill and dump the first two RO tanks to stabilize taste and remove fines.

- Leak check: Pressurize, then wipe each fitting with a tissue—any dampness means re‑seat and re‑tighten.

- Fridge/ice tee (optional): Use certified tubing and a shutoff valve; label line at the fridge for future service.

Whole‑Home Carbon (Backwashing Tank)

- Location: Install before the water heater; leave room for valve access and media service.

- Bypass: Add a full‑port bypass for maintenance; secure the drain to an approved receptor.

- Start‑up rinse: Backwash to clear fines until water runs clean, then place in service.

- Program backwash: 2–3 times per week (typical); adjust by local sediment load.

- Pair with RO: Use whole‑home for house‑wide particle reduction, then RO at the sink for drinking/cooking quality.

13) Commissioning: Prove Your System Works (Simple Checks)

- Baseline TDS: Measure tap TDS; then measure RO water TDS after two full tank cycles. Expect a large drop (e.g., 250 → < 50 ppm).

- Flow test: Fill a clear glass; look for clarity and absence of specks. Clear ice over 24 hours is another great sign.

- Pressure & taste: Confirm steady flow at the faucet; no plastic taste after break‑in flush.

- Log install date: Write dates on cartridges with a marker; add reminders for replacements.

14) Quick Troubleshooting Preview (Full Flowcharts Coming in Part 3)

Water tastes “flat”

- Flush 2–3 full RO tanks after install

- Ensure post‑carbon is installed and oriented correctly

- Optional: add a mild remineralizer for taste balance

Slow flow at faucet

- Check tank air pressure (7–8 psi empty)

- Replace prefilters if older than 12 months

- Inspect tubing for kinks; verify saddle/angle‑stop fully open

Cloudy water initially

- Normal micro‑bubbles during first hours; clear after flushing

- Ensure carbon fines are rinsed (run faucet a few minutes)

Filter clogs quickly

- Step up sediment staging (10 → 5 → 1 μm)

- Add whole‑home pre‑filter if well sediment is high

Full troubleshooting trees—including leak checks, tank pressure charts, and TDS diagnosis—arrive in Part 3.

15) Ready to Choose? Start With These Two Paths

Point‑of‑Use (Kitchen‑First)

Maximize drinking/cooking quality with a compact under‑sink RO. Add a tee for fridge/ice.

Shop Under‑Sink ROWhole‑Home + Kitchen RO

Reduce particles across the home with a carbon tank, then polish to perfection at the kitchen with RO.

16) Troubleshooting Flowcharts: Diagnose → Fix → Verify

Use these symptom-based trees to quickly restore performance. Each ends with a verification step so you know the issue is solved before you walk away.

Tree A — “Water still looks the same” (no visible improvement)

- Flush properly: After install or filter change, run the faucet for 3–5 minutes and discard the first 2 RO tank fills. Carbon fines can cloud the first glasses.

- Check staging: Confirm order: Sediment → Carbon block → RO membrane → Post‑carbon. Reverse order = poor results.

- Micron mismatch: If your water has high turbidity, add a 10 µm prefilter before 5 µm → 1 µm. Depth‑then‑tight captures more particles.

- Whole‑home pre‑load: If showers or laundry are cloudy, add/clean a whole‑home sediment + carbon stage to reduce house‑wide particle loading.

- Verify: Pour into a clear glass under strong light. You should see no specks and rapid bubble release.

Tree B — “Flow is slow at the RO faucet”

- Measure tank air pressure empty: 7–8 psi is ideal. Adjust with a hand pump if needed.

- Replace prefilters older than 12 months (or earlier if pressure drop is obvious).

- Inspect tubing routes for kinks; verify angle‑stop/ball valve is fully open.

- If feed pressure is consistently < 45 psi, add a booster pump (or choose a higher-GPD membrane rated for low pressure).

- Verify: Time how long it takes to fill a 12 oz glass. With a healthy tank, it should be just a few seconds.

Tree C — “Taste is flat / plastic”

- Ensure you flushed 2 full RO tanks post‑install.

- Confirm the post‑carbon (polish) cartridge is installed in the correct direction (follow flow arrows).

- Swap in a fresh post‑carbon if taste remains (some palates prefer a mild remineralizer after RO for “body”).

- Check fridge/ice tee line for stagnation; flush until cold and clear.

- Verify: Brew tea/coffee; bitterness should drop and sweetness rise with balanced water.

Tree D — “TDS higher than expected” (after RO install)

- Discard the first two tanks; measure again. Early readings run high during membrane break‑in.

- Measure feed TDS and permeate TDS; calculate rejection %. A healthy membrane often shows > 80–90% drop.

- Check for cross‑connections (RO outlet accidentally tied to unfiltered cold line).

- Replace prefilters if clogged; low flow can reduce rejection. Confirm membrane is fully seated in the housing.

- Verify: Record TDS weekly for three weeks; values should stabilize low and steady.

Tree E — “Leaks or damp fittings”

- Depressurize system. Re‑cut tubing squarely; push fully into quick‑connects (past the O‑ring) and tug gently to seat.

- Replace worn collets/O‑rings (keep spares on hand).

- Apply 2–3 wraps of PTFE tape on threaded metal fittings only (not on compression or quick‑connects).

- Verify: Dry with a tissue, repressurize, then re‑check after 10 minutes; tissue should stay dry.

Tree F — “Frequent filter clogging”

- Step up sediment staging: 10 µm → 5 µm → 1 µm before carbon.

- Add a whole‑home sediment filter to catch the bulk load upstream.

- Check for construction/rust events in municipal lines; replace cartridges after major main breaks.

- Verify: Pressure across prefilters should improve; set calendar reminders for more frequent changes.

Tree G — “Cloudy water right after filter change”

- Most cloudiness is harmless micro‑bubbles and carbon fines. Flush 3–5 minutes.

- Ensure cartridges match flow direction; incorrect orientation can shed fines downstream.

- Verify: Leave a glass for 2 minutes; bubbles should rise and disappear quickly.

17) Maintenance Schedules & Service Reminders

Consistent maintenance is the difference between “pretty good” and “bottled‑quality” water. Use these practical schedules.

Under‑Sink RO + Carbon Block

- Sediment prefilter: 6–12 months (sooner with high turbidity).

- Carbon block: 6–12 months (taste/odor returns sooner in heavy use).

- RO membrane: 24–36 months (track rejection % via TDS).

- Post‑carbon polish: 12 months.

- Tank pressure check: yearly at 7–8 psi (empty).

Whole‑Home Sediment + Carbon Tank

- Sediment cartridges: 3–6 months (or by pressure drop).

- Backwashing carbon: program 2–3× per week; media life 3–5 years typical.

- Valve inspection: semi‑annual (drain line secure, cycles properly).

- Annual pH & turbidity check.

Storage & Sanitation Tips

- Store spare filters sealed, cool, and dry. Do not freeze RO membranes.

- Sanitize the RO tank and faucet annually with manufacturer‑approved procedures.

- Label each cartridge with install date and target change date.

18) Performance Optimization: Clarity, Taste & Longevity

Clarity & Particle Control

- Use depth sediment filters before tight micron blocks to resist clogging.

- If water is consistently dusty after municipal repairs, add a whole‑home sediment stage.

- Keep flow rates within the cartridge’s rating; excessive flow can turbinate fines.

Taste & Remineralization

- RO can taste “too pure” for some. Add a light remineralizer to lift TDS into the 60–120 ppm range for a rounder mouthfeel.

- For coffee/tea, many programs target ~75–150 ppm TDS, low alkalinity, and neutral pH for sweet extraction.

- Replace post‑carbon annually—fresh carbon restores “crispness.”

Extend Filter Life

- Change sediment on time to protect the carbon and membrane.

- Keep an eye on pressure drop; rising ΔP means it’s time to swap cartridges.

- Install a small pressure gauge before/after prefilters on demanding setups (cafés, offices).

19) Measure & Verify: A Simple Home QC Plan

Trust but verify. Here’s a light‑touch quality‑control plan you can run in minutes each month.

Monthly QC Checklist

- ✔ TDS log: record tap vs RO TDS; aim for stable low RO TDS.

- ✔ Flow check: fill a 12 oz glass; time should be consistent across months.

- ✔ Visual check: glass clarity and ice transparency remain high.

- ✔ Taste notes: any plastic/flat notes? If yes, change post‑carbon or add light remineralization.

- ✔ Leak sweep: tissue test on fittings after filter changes.

QC Log (Copy/Paste)

Date: __________

Tap TDS: _______ ppm RO TDS: _______ ppm

12 oz Fill Time: _______ sec Tank Pressure (empty): ______ psi

Taste/Clarity Notes: ___________________________________________

Filters Changed: _______________________________________________

Next Change Due: ______________________________________________

20) Reduce Microplastics at the Source (Home Habits)

Filtration solves what reaches your glass. These simple habits reduce microplastic loading in the first place—good for your home and the environment.

- Laundry fibers: Wash synthetics in cold water on gentle cycles; consider using a microfiber capture bag or external washer filter to reduce shedding into drains.

- Kitchen plastics: Avoid cutting hot foods in plastic containers; prefer glass or stainless steel for hot liquids.

- Replace worn plastics: Aging gaskets and hoses can shed fragments; upgrade to higher‑quality parts as needed.

- Outdoor habits: Keep driveways clear of debris; tire and paint particles wash into storm drains during rain.

21) Extended FAQ — Microplastics, Nanoplastics & Home Filtration

Q1. Do RO systems remove microplastics?

Yes. Reverse osmosis acts as a near‑absolute barrier for microplastics and significantly reduces nanoplastics. Pair with sediment + carbon prefilters for best results and membrane protection.

Q2. Will a water softener remove microplastics?

No. Softeners exchange hardness minerals (calcium/magnesium) and don’t target particles. Use a softener plus sediment/carbon and RO for complete water quality.

Q3. Is boiling effective for microplastics?

No. Boiling concentrates solids as water evaporates. Use filtration, not heat.

Q4. Are UV or ozone helpful?

They inactivate microbes but don’t remove particles. Use UV with filtration if microbiological control is also a goal.

Q5. How often should I change filters?

See Section 17, but a useful shorthand is: sediment 6–12 months, carbon 6–12 months, RO membrane 24–36 months, post‑carbon 12 months—or sooner if taste or pressure changes.

Q6. Why does my water taste “flat” after RO?

RO removes most dissolved solids, which some palates interpret as flat. Add a light remineralizer or post‑filter tuned for taste to restore mouthfeel while keeping particles out.

Q7. Do whole‑home systems eliminate all microplastics?

They greatly reduce house‑wide particle load and protect fixtures, but for drinking/cooking quality, add a point‑of‑use RO at the kitchen for the tightest barrier.

Q8. Is bottled water safer?

It varies by brand and handling. A home RO + carbon setup gives consistent quality and removes dependence on bottle sources.

Q9. Can I feed my fridge/ice maker from RO?

Yes. Use certified tubing and a shutoff valve. Expect clearer ice and better taste once the system is flushed.

Q10. How do I know the system is working against microplastics I can’t see?

Track TDS (for overall membrane performance), check clarity/ice, and follow the QC log. If you need lab confirmation, some services offer microplastics screening as a baseline.

22) Quick Summary: What Works Best (and Why)

- For drinking & cooking: Under‑sink RO with sediment + carbon prefilters and a post‑carbon polish.

- For whole‑home comfort: Add a backwashing carbon tank and staged sediment filtration.

- For taste: Optional remineralizer after RO, especially for coffee/tea programs.

- For longevity: Stick to the maintenance schedule and keep a simple QC log.

23) Case Studies: Real‑World Results with Multi‑Stage Filtration

Below are condensed, real‑world–style scenarios that illustrate how layered filtration solves microplastics concerns while improving taste and clarity for homes, offices, and cafés.

Case A — Family Kitchen (4 people)

- Challenge: Cloudy ice and “plastic” note in tap water after neighborhood main repairs.

- Solution: Under‑sink RO (100–200 GPD) with 5 μm sediment → 1 μm carbon block → RO → post‑carbon. Tee line to fridge/ice.

- Install Time: ~90 minutes DIY.

- Result: Clear ice within 24 hours; improved taste; kids drink more water; coffee less bitter.

- Upkeep: Prefilters 6–12 months; post‑carbon 12 months; membrane 24–36 months.

Case B — Apartment / Office

- Challenge: Landlord restrictions (no drilling), bottled water costs, mixed taste from tap.

- Solution: Countertop RO unit with integrated sediment/carbon.

- Result: Consistent clarity and taste; reduced plastic bottle purchases; easy filter swaps.

- Upkeep: Annual cartridge kit; wipe exterior monthly; sanitize reservoir per manual.

Case C — Café / Specialty Tea Bar

- Challenge: Inconsistent extraction and dull flavors; micro‑residue in kettles.

- Solution: Under‑sink RO feeding brew bar + taste‑tuned post‑filter; QC log for TDS and flow.

- Result: Brighter, sweeter cups; fewer kettle cleanings; clear ice.

- Upkeep: Prefilters 6 months; post‑carbon 12 months; membrane 24–36 months; log TDS weekly.

Case D — Whole‑Home Comfort + Kitchen RO

Challenge: Family with well water experiencing visible specks in showers and laundry lint buildup.

- Solution: Whole‑home sediment + backwashing carbon tank to reduce house‑wide particle load; under‑sink RO at the kitchen for drinking/cooking.

- Result: Cleaner fixtures, clearer showers, softer laundry feel; crystal‑clear kitchen water.

- Upkeep: Replace sediment as needed (3–6 months); backwash carbon 2–3×/week; kitchen RO per schedule.

24) One‑Page Executive Summary: Microplastics & Your Best Defense

What are we solving?

- Microplastics (1 μm–5 mm) and nanoplastics (< 1 μm) enter drinking water via municipal mains, runoff, and distribution wear.

- Particles can carry other substances on their surfaces and leave residue in appliances.

What actually works?

- Point‑of‑use RO + sediment + carbon = best day‑to‑day protection for drinking/cooking water.

- Whole‑home sediment + carbon reduces house‑wide particle load; pair with RO at the kitchen.

- QC plan: Track TDS, clarity, and taste monthly (see Section 19).

What should I buy first?

- Family homes: Under‑sink RO (100–200 GPD) + fridge/ice tee.

- Apartments: Countertop RO (no drilling).

- Cafés: Under‑sink RO + taste‑tuned post‑filter; keep a QC log.

25) Buyer’s Checklists & Comparison Tables

25.1 Under‑Sink RO Quick Checklist

- ✅ Space for bracket, tank, and faucet line

- ✅ Cold‑water angle stop and drain connection available

- ✅ Plan stages: 5 μm sediment → 0.5–1 μm carbon block → RO → post‑carbon

- ✅ Tee to fridge/ice (optional) with shutoff valve

- ✅ Install date labeled; filter change reminders set

25.2 Whole‑Home + Kitchen RO Checklist

- ✅ Location before water heater with floor drain access

- ✅ Bypass valves installed for service

- ✅ Backwash programmed (2–3×/week) and verified

- ✅ Kitchen RO sized for family demand (see Part 2 Sizing)

- ✅ TDS/taste QC log created

25.3 At‑a‑Glance: Technology Comparison

| Tech | Particle Control | Dissolved Contaminants | Flow/Use | Best Use |

|---|---|---|---|---|

| Sediment (1–5 μm) | Good (≥5 μm) | No | High | Prefilter for any system |

| Carbon Block (0.5–1 μm) | Very good (sub‑micron) | Organics, taste/odor | Moderate | Pair with RO or UF |

| Ultrafiltration | Excellent (microplastics) | Limited | High | High flow applications |

| Reverse Osmosis | Near‑complete | Yes (broad spectrum) | Point‑of‑use | Drinking/cooking |

26) Printable Microplastics Filtration Planner (Copy/Paste)

Home/Business: _____________________ Date: __________

Users: _____ Daily drinking/cooking gallons: _____

Target Setup (circle): Under‑sink RO Countertop RO Whole‑home + Kitchen RO

STAGES & MODEL NOTES

Sediment: ______ μm (depth?) Change: ____ months

Carbon Block: ____ μm Change: ____ months

RO Membrane: ____ GPD Change: 24–36 months

Post‑Carbon: __________ Change: 12 months

Optional: Remineralizer? Y / N

CONNECTIONS

Faucet installed? Y / N Fridge/Ice tee? Y / N

Tank pressure (empty): ____ psi (target 7–8 psi)

QC LOG (Monthly)

Tap TDS: ____ ppm RO TDS: ____ ppm Taste: □ crisp □ flat □ other: _______

Flow time (12 oz): ____ s Ice clarity: □ clear □ cloudy

27) Quick Links & Next Steps

Get Help

Send us your household size, water source, and any goals (fridge/ice line, coffee program). We’ll recommend a complete package.